At the end of the last blog post, we explained how Antoni Gaudí, after realising that solid stone columns would have to be too thick, decided to use reinforced concrete to create svelte columns inside the Sagrada Família. But what is this material and how is it used at the Temple?

Characteristics and components of reinforced concrete

Concrete is made up of gravel, sand and water (needed to kick off the reaction of the cement so it will start to set) and cement, which is like glue holding together the rest of the ingredients.

Concrete, like any rock, can be very strong when compressed, but doesn’t stand up as well against tensile stress. So, to make up for this weakness and create a material that can stand up to all types of stress, steel is put into the concrete to create reinforced concrete.

When was this material first used?

Building with cement and concrete may seem very modern, but these materials were used in Roman times. We can look to Pozzolanic cement, used by Roman engineers to build water channels, piers and watermills after they discovered this material can harden underwater. The name comes from the town of Pozzuoli, on the slopes of Mount Vesuvius in Italy, and the most well-known example of building with this type of cement is the Pantheon in Rome, from 123 AD. Its lightness without sacrificing strength is one of the great qualities of this material, which is why it was used to build the great dome of the Pantheon: with its diameter of 43.3 metres, it is still the largest made of unreinforced concrete in the world to this day.

It took nearly two millennia to surpass this size and it was possible thanks to innovations in reinforced concrete, which was first used by Italian architect Pier Luigi Nervi in the 1960s.

The first cement factory in Catalonia, owned by Eusebi Güell

Eusebi Güell, Gaudí’s protector and patron, was the Catalan industrialist who promoted the first factory to extract and produce Portland cement in Catalonia and Spain, in 1901. It was the Asland cement factory, in Castellar de n’Hug, near the source of the Llobregat River.

Gaudí’s close relationship with Mr Güell, also in terms of this company, can be clearly seen in his works that remain in the area, including the house in Catllaràs for the engineers heading up the extraction of the coal needed to fuel the ovens in the cement factory. With little wagons and funiculars, they brought the material down from the Catllaràs mountains to Clot del Moro, where the factory was located.

(left) Current state of the former Asland cement factory, in Castellar de n’Hug / (right) Xalet de Catllaràs, in Pobla de Lillet, designed by Antoni Gaudí in 1902 and renovated in 2020.

Sugranyes, Gaudí’s collaborator and expert in calculating concrete

Nevertheless, Eusebi Güell wasn’t the only person around Gaudí who had ties to concrete. So did Domènec Sugranyes, who was one of Gaudí’s close collaborators and even became his right-hand man from 1914.

Sugranyes became a professor at the Escola del Treball in 1923. There he gave classes in Construction, Elementary Mechanics and Geometry, and the notes he made up for his classes show how, using graphic calculations, he not only passed on to his students what he had learned in Gaudí’s workshop regarding the funicular load transfer in calculating arches and vaults, but also pushed this knowledge forward and used the same tools (straight edge and compass) to develop graphic calculations for reinforced concrete.

Gaudí, pioneer in reinforced concrete

Given both his proximity to the first cement factories and quarries in the country and having experts in calculating cement in his workshop, it makes perfect sense that Gaudí was a pioneer in our country in using reinforced concrete. The descriptions of Joan Bergós, Gaudí’s biographer, and those in the Sagrada Família magazine paint an in-depth picture of Gaudí using concrete structured with metal elements on La Pedrera, the pavilions at Park Güell and the auxiliary buildings for the workshops at the Sagrada Família, among others. César Martinell, another Gaudí biographer, also says the architect abandoned the original idea of building the Sagrada Família vaults with paraboloids and turned instead to hyperboloids when he became aware of the growing possibilities that reinforced concrete had to offer.

One example of reinforced concrete at the Sagrada Família is the spires of the towers on the Nativity façade.

Moreover, Gaudí proposed using concrete to build the inner columns and nave vaults, as has been done, which can be seen in the conference on the structural system for this project that Sugranyes gave at the Association of Architects of Catalonia in 1923. In his talk, he went into great detail on the transfer of the building’s loads that would have to be absorbed by the reinforcements in the concrete on the three levels of superimposed vaults and roofs on the nave.

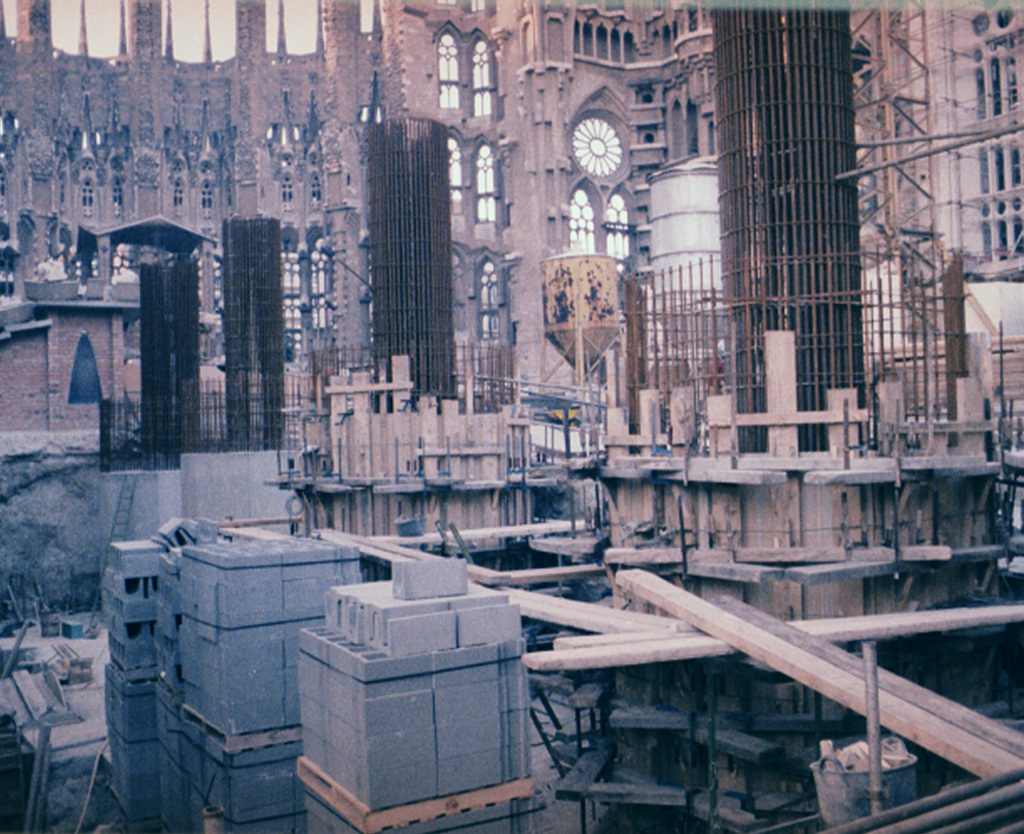

Rebar structure for building the interior columns at the Basilica (left) and the vaults in the central nave (right)

The reinforced concrete of today, and at the Sagrada Família

However, the reinforced concrete Gaudí used was different from that used today, which has evolved thanks to technology.

One example of these improvements is its resistance to breaking under simple compression forces. Around the 1970s, in the construction sector, it was common to use cement with a characteristic strength of 175 kg/cm2, especially for foundations, but soon after regulations began requiring values of 200 kg/cm2 for all structures. Today, civil works must guarantee at least 250 kg/cm2 for any cement structure.

For the Sagrada Família, however, cement with 350 kg/cm2 is used for smaller structures and for important ones, 600 kg/cm2, as is currently being used on the tower of Jesus Christ. Laboratory results often confirm that the worksite makes cement that is four times stronger than the conventional type. Plus, as it is much more compact and denser, it is also more resistant to erosion and deterioration due to atmospheric agents.

This concrete has been made possible by collaborating with university research centres, which have introduced new formulas for its composition.

So, the reality is that regulations have regularly increased the requirements for structures, and the extraordinary increase in the needs of the worksite has also made it essential to improve the cement commonly used. In this regard, boosting the strength was practically the only alternative to meet the new requirements, particularly regarding seismic activity and wind, as the size of the structural elements (the diameter of the columns, the thickness of the walls, etc.) could not be altered and still remain totally true to Gaudí’s original designs.

Reinforced concrete structure for building the vaults of the side nave, in 1995.